Description

Bluewater's professional range of osmosis units, and in particular the PRO-600, is ideal for applications requiring large quantities of osmosis water, such as laboratories and cosmetics preparation. In industrial applications, such as electroplating or electroerosion baths, final rinsing of parts after washing, preparation of cutting emulsion in fine mechanics, the high reliability and robustness of the Pro series are highly appreciated.

Trade and food industry, professional and gastronomic kitchens can rely on the high and continuous throughput of the Pro 600. It is very easy to install, does not require any pre-treatment of the water, even when it is very hard, and is discreet and perfectly suited to the kitchen. Its compact design and standardised dimensions allow it to be fitted into a closed cabinet or under a worktop.

Economical in terms of electricity and with a recycling rate of over 60% of water, it is the most efficient reverse osmosis system on the market. It produces at least 5 to 6 l/min of RO water directly and with a daily average of 4.8 l/min.

How the Pro 600 works

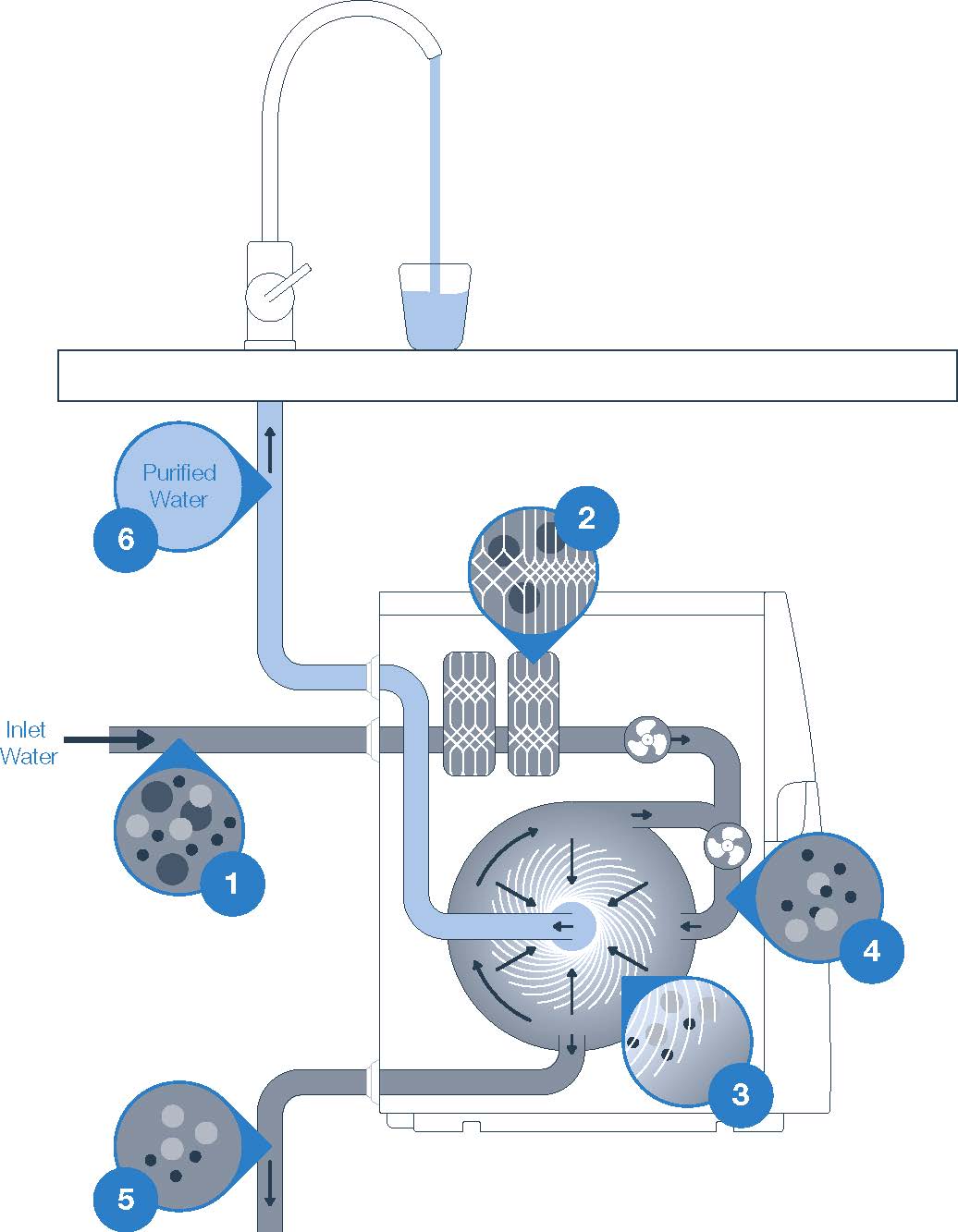

Bluewater's Pro systems operate on the principle of reverse osmosis which is developed in several stages:

- The water arrives with its impurities

- The water is coarsely filtered.

- The pure water, the filtrate, passes through the osmosis membrane

- The impurities are carried away with the current and return to the primary water circuit, tangential to the osmosis membrane.

- This results in the concentrated liquid.

- The surplus is removed

- The filtrate is ready for consumption

Membrane treatment systems are high efficiency treatment systems that separate impurities from water and are one of the best known applications of Reverse Osmosis, which allows the production of high quality water at an attractive price.

The Pro 600 can be used alone or integrated into a water treatment system to achieve even higher quality.

Specifications

Flow rate: Average flow rate of 4.8L/min for a total of 6912 l/day

The Pro 600 runs continuously for 10-12 minutes and then has to discharge the concentrate which decreases its instantaneous flow rate.

Dimensions and weight: 46.6 cm x 22.5 cm x 29.5 cm (height x width x depth)

Inlet parameters: Hardness < 30°f, conductivity < 2'000µS/cm, pressure > 0.2 bar

Output parameters: Pressure 2,5 bar minimum / 10 bar maximum

Special features

- Integrated activated carbon filter (chlorine removal)

- No downstream pressure water tank required

- Produces 4.8 l/min of water

- Automatic water control - LED display

- Patented automatic rinsing system ensures long membrane life and allows the plant to be used even with hard water

Using the Pro-600

The Bluewater PRO-600 produces purified water from virtually any water source:

- Municipal water

- Well water

- Brackish water

- ...

It removes contaminants such as:

- Lead

- Microplastics

- Chemical and pharmaceutical residues

- Clean and purified water sheets

- ...

It can be used for various applications:

- Food service

- Hospitals

- Laboratories

- Garages

- Restaurants

- Even for the private sector

- ...

Bluewater Pro-600 and Chlorothalonil

Bluewater Pro-600 can also be used against the pesticide biocide CHlorothalonil. It can be used to treat water and eliminate this substance which is now considered toxic according to the new European and Swiss laws.